Latest News

Facade panels for Bjørvika “punching work for tinsmith January 2019”

After an inquiry from tinsmith Øivind Nilsen, we started the production of shillings (facade panels) in different sizes for B7 (building) in Eufemiasgate in Oslo. The customer was responsible for the cost of the material 6WL, ColourTex® stainless steel, from the supplier Rimex Metal (Australia). The material was shipped from the UK. The appearance the facade should have and the surface treatment was crucial for the choice of this material with this special bubbling surface structure.

The stainless steel is immersed into a hot aqueous solution contained in heated tanks. A natural reaction leads to a thickening of the chromium oxide layer which in turn leads to light interference effects between the surface of the film and the surface of the stainless steel. This results in a breakdown of reflected white light and creates a perception of colour.

The perceived colour moves through a spectrum of colours as the thickness of the chromium oxide layer is increased on stainless steel. The visible “color” is a “vibrant color” that will change with the angle the eye sees and the environmental lighting. The tinsmith workshop quickly got the finished pennies and worked in parallel to break up the fasteners.

Quality:Aisi 316L, Surface:Granex M1A,Color: Rosy Gold, Pattern:6WL Reverce

The facade project was successful and the expression was both striking and unique.

Kragerud kindergarten visit 2019

Pre-school group visits Friday 7th June 2019

For us as a company it is an investment that preschool children bring with them a positive and fascinating experience from an industrial visit.

“Skilled workers of the future”

Children have the ability to get excited, dream, get inspired or get engaged. Children live into the world of technology. Therefore, it is important that we can help the children take this experience further into life.

We have a social responsibility and are committed to many areas according to laws and regulations. Nevertheless, we find it much nicer with social involvement that is not committed but entirely voluntary.

We see that Smartphone’s and digital media have done something about our society, both positively and negatively. Smartphone’s have come to stay, so our corporate responsibility is to engage and motivate the new generation of skilled workers in a different way.

F1 Brussel 2018

F1 Brussels 2018 Trip to HAAS Automation Europe in Belgium. KMG was invited under the auspices of HMS maskin AS, which is a supplier of HAAS in Norway.

Guided tour of Haas Automation, lunch and qualifying rounds on the big screen. Dinner with the Haas F1 Team. Day trip to the Circuit de Spa-Francorchamps with Formula 1 race.

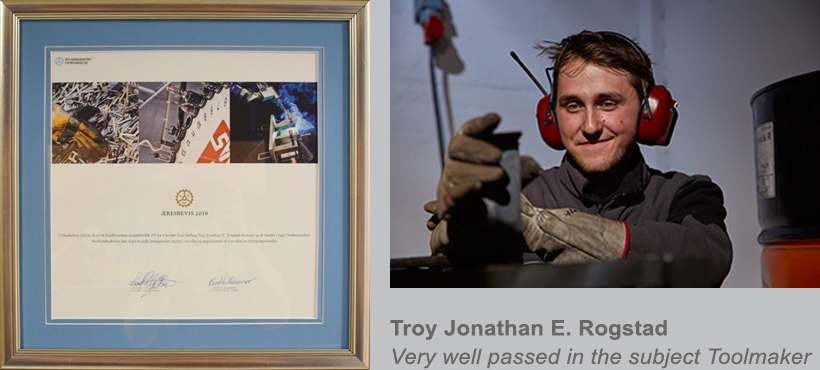

The honor certificate 2018

Our company has for the second time been awarded the award, ÆRESBEVIS, by OKMF (Training Office for Mechanical subjects). The first award we received in 2011 to have brought an apprentice to a very well-passed exam in the subject Toolmaker.

The honor certificate is a tribute to all member companies in OKMF, which creates a good learning environment, and has shown determination and dedication to develop skilled professionals with very well-passed examinations.

The first to have a link to the website on the certificates from NEMKO

The organization was challenged by Nemko’s auditor at the re-certification audit 2-3. October 2017. “Is the organization ready to sell its scope and compliance in a new modern certificate text of only 3 lines”, ask the auditor? We threw the ball back to the auditor about the possibility of using the link to the website in connection with the text on the certificate. The auditor thought that the time has come for asking the question to Nemko! “If so, KMG will be the first to have a link to the website”, the auditor encouraged.

At the very beginning of November we received mail from the manager of Nemko’s certification department that the link to the website in the certificate was a very good proposal that would be fulfilled. We immediately sent the suggestion for new text to the certificates.

The certificates with new text and link to the website were updated and signed by Nemko’s Manager of Certification Department on November 3, 2017.

Development and production services of stamping tools and machines for the industry. Technological innovation and production of stamped and machined products and services. Selection of materials considering a life cycle perspective of products. www.kmg.no

Jubilee trip to Svalbard

Teambuilding 13-15. October 2017

In connection with our 100th anniversary, the company arranged a trip to Svalbard for all employees.

As part of strengthening the team spirit of the KMG team, we chose a trip completely out of the ordinary.

Among the activities was arctic deep sea fishing, ATV driving, polar expedition with MS Langesund, brewery visits, coal mines, dog sledding and many other cultural events. With a low cloud cover, it seemed unlikely that we would see the northern lights, but with all the luck the low cloud cover opened and a beautiful green light phenomenon turned out. We could not have asked for a more amazing start to our anniversary trip.

HAAS Turning Center

March 2017

KMG is starting the new year by investing in new technology. When the requisition of a brand new HAAS DS 30ssy Dual Spindle Turning Center/Lathe saw a much shorter expected delivery time than anticipated, Team KMG had to come up with some quick solutions in week 10 of the year. With prompt planning, timely initiative, and goal oriented decisions, parts of our production and tool department were broken apart and reassembled to account for the coming addition.

On the morning of Friday March 10th, the expectations of the whole company were high. Ask Industri Montasje AS was present to handle a risk-free movement of the wonder machine. At around 8 am, a semi-truck with Dutch plates pull up to the gates with the expected delivery. After a thorough analysis by the experts, the movement of the HAAS DS from the truck to gate 3 began. New technology is a reality.