CNC Enginering

Karl M. Gulbrandsen has skilled employees that strengthen the quality and results according to the costumers wishes and demands.

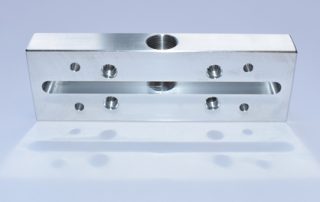

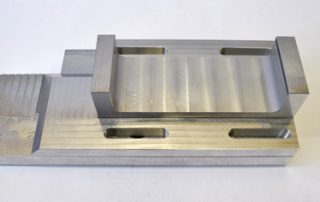

We produce of everything from prototypes to large series productions, as well as dealing with repairs or modifications.

We can process everything from hand drawn sketches to 2D and 3D drawings in most formats for documentation and programming to machining.

We are experienced with chip forming machinery in most materials:

- Aluminium: 2024, 5052, 6082 T6, Certal and Alumec 89

- Steel: ST-37, SS 1650, SS 2260, Arne, Sverker, ASP 2005, Vanadis 4 Extra SuperClean and cured tool steel up to 70HRC

- Stainless 304, acid resistant 316 and Super Duplex

- POM, PEEK

- Wood

Machines:

Haas VF4SS with control prepared for 4 and 5 axis simultaneous machining.

Workspace X: 1270mm Y: 508mm Z: 635mm. 12000Rpm.

Haas DS-30SSY with big bore option (76mm), CNC-lathe with bar feeder, subspindle, Y-axis and 24 station turret (12 Live tools). Workspace: X: 318mm Y: +/- 50.8mm Z: 584mm. Main spindle: 4500Rpm Sub spindle: 4800Rpm Livetool: 6000Rpm.

Maho 500, horizontal machine with removable vertical head. 2,5 axes steering, workspace X: 500mm Y: 400mm Z: 300mm. 3000Rpm

ISO:9001, ISO: 14001, and OHSAS:18001